A Comprehensive Guide to Traffic Deck Coatings: Restoration and Installation Applications

- Details

Traffic Deck Coatings (TDCs) are pivotal in extending the lifespan of our concrete structures. These coatings not only enhance aesthetics but also provide protection against environmental and mechanical wear.

However, achieving optimal performance requires a meticulous approach throughout its lifecycle. This guide offers a comprehensive look into the nuances of TDCs, ensuring professionals achieve best-in-class results when considering the factors we outline.

What Are Traffic Deck Coatings?

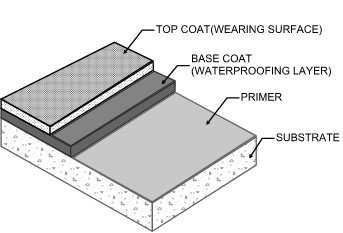

Traffic Deck Coatings (TDC) are multi-layered systems, primarily utilizing one or two-component polyurethane. Designed to shield concrete from moisture and contaminants, they consist of a primer, waterproofing base coat, and a wear course layered with topcoat and aggregates. Two-component systems cure notably faster than their single-component counterparts, expediting application and structure readiness.

TDCs are prevalent across North America in external concrete structures and parking decks. They offer waterproofing, enhanced non-slip surfaces, and light reflection in enclosed parking areas. Their thin dual-layer design is advantageous, enabling visual and acoustic assessments of the coating and underlying concrete.

How TDCs Can Help Safeguard Against Concrete Deterioration

Concrete deterioration results from the infiltration of moisture and contaminants like de-icing salts and chlorides. This penetration corrodes the embedded steel reinforcement and interferes with the cement matrix's chemicals, leading to surface scaling. As these agents delve deeper, the steel rusts and expands, fracturing the surrounding concrete.

When this steel exposure continues, it further expands, causing the concrete to detach, especially near structural elements like columns, compromising load-bearing capacities. Central slab deterioration affects the structure's load-carrying ability, while deterioration on slab undersides and edges can result in hazardous falling debris.

Furthermore, moisture and contaminants can corrode unbonded post-tensioned reinforcement, impacting steel strands within the structure and reducing the structure's load-bearing capacity. This deterioration can be mitigated using Traffic Deck Coatings (TDCs), forming a protective shield against water and contaminants.

3 Common Challenges in Traffic Deck Coatings

Traffic Deck Coatings (TDC) play a vital role in protecting concrete structures, but over time, they may face a series of common challenges. These issues, if left unattended, can compromise the efficacy of the coatings and lead to greater structural problems.

1. Debonding

Debonding involves the coating's detachment from the substrate or between its layers. Causes include prolonged use, inadequate surface prep, moisture in the slab during application, water migration, or unsuitable application timing. As the coating undergoes wear, specifically in areas like drive aisles, water can weaken the bond between the waterproofing and concrete. Factors like moving vehicles and temperature variations can worsen debonding, especially if layers don't adhere well due to poor surface prep or unsuitable curing conditions.

2. Cracks and Scrapes

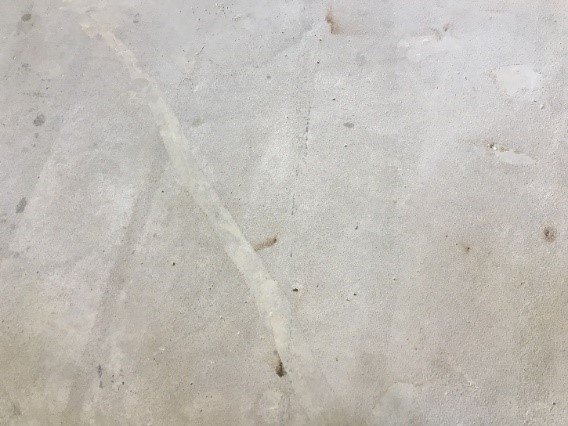

Concrete substrate movements—whether from shrinkage, thermal changes, or load deflection—can cause TDC cracks. In new structures, these cracks can emerge within the first year of service life. In older buildings, cracks emerge as the TDC becomes brittle with age.

Regular traffic can also introduce scrapes, especially in industrial settings or loading docks. In cold regions, power brushes are recommended over snowplows to avoid scraping. Proper detailing according to manufacturers' recommendations is essential. For instance, per CSA S413-21, specific crack sizes dictate pre-stripping with base coat or sealing with compatible sealants before base coat application.

3. Surface Wear

A TDC's aggregate surface undergoes wear from consistent wheel traffic, exacerbated by excess gravel or sand. Initial wear signs include aggregate pop-outs, indicating abrasion on the wear course top. As wear continues, the underlying waterproofing membrane gets exposed, and further wear could expose the concrete substrate, leading to debonding and potential moisture penetration.

Layers of Success: How to Maximize Service Life with the Right Steps

Traffic Deck Coatings can exhibit extended service lives when specific layered approaches are used. It's paramount to be proactive in each layer's implementation, guaranteeing a superior, durable coating.

1. Surface Preparation

A foundational step, surface preparation, is essential for effective TDC application. Employ shot blasting to reach an ICRI Concrete Surface Profile (CSP) 3-4, eliminating concrete's micro-fractures and laitance. This paves the way for solid coating adhesion. During repairs, this method removes debris and contaminants like grease.

It's key to maintain the right profile: too smooth may lead to debonding, while overly rough necessitates an epoxy grout coat to level out, especially in compromised areas.

2. Application Environments

Material selection should align with service life conditions. High-traffic or industrial zones might demand robust surfaces, such as hybrid TDCs or advanced systems like PMMA or PUMA. Proper phasing and curing temperatures are critical to bond strength and durability. If portions of a facility remain operational, protective measures like signage and barriers are essential to prevent contamination.

3. Thickness & Testing

Meeting manufacturer specifications ensures the coating's endurance. For new concrete or external applications, checking the moisture content is crucial to avoid potential debonding due to vapour drive. Thickness consistency is vital: overly thin coatings risk premature wear, while excess thickness can cause debonding. Two-component products benefit from wet film testing, allowing for real-time adjustments. Single-component products, on the other hand, require cut testing to ensure optimal thickness. Adhesion testing, guided by CSA A23.2-6B standards, provides insights into the coating's bond strength.

4. Tricky Details

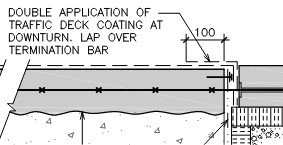

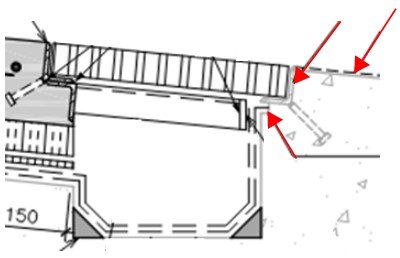

While the main slab area may be straightforward to coat, edges and terminations demand extra attention. Techniques such as ground/saw cut reglets boost mechanical adhesion and deter moisture intrusion. Special attention at cracks and upturns ensures no moisture buildup; for example, a double membrane application provides added resistance.

For smooth transitions, methods like a two-component sealant heel bead can aid in sealing and moisture deterrence. For anchored structures, surface preparation is a must, with corrosion removal ensuring the longevity of the embedded components.

5. Compatibility

When working with polyurethane-based TDCs, understanding existing coatings is fundamental. If the existing coating is different, like a bitumen-based one, interactions can lead to discoloration or brittleness in the TDC. To navigate this, deploy intermediate layers or materials, such as steel termination bars or versatile compounds like PUMAs/PMMAs, to bridge the compatibility gap.

Conclusion: Maximizing Durability through Effective Traffic Deck Coatings

Proper specification, design, application, and assessment of traffic deck coatings are the cornerstones of their intended performance and longevity. To bolster this foundation, annual condition reviews, as recommended by CSA S413, serve as a proactive measure. By catching wear and damage early, these reviews can preempt costly structural repairs. Additionally, ensuring the right choice of materials, coupled with meticulous surface preparation and diligent installation monitoring, lays the groundwork for a successful project.

This thorough approach not only minimizes potential warranty issues but also, with an informed understanding of concrete deterioration and a commitment to best practices, ensures the extended service life of traffic deck coatings.

Take Action with RJC Engineers

When it comes to preserving and maximizing the service life of your infrastructure, don't settle for less. RJC Engineers is an industry leader in delivering innovative solutions for traffic deck coatings and structural enhancements.

With decades of expertise and a commitment to excellence, our team ensures that every project receives unparalleled attention and technical acumen. Contact RJC Engineers today to discuss tailored solutions that stand the test of time.